Six Sigma has been gaining momentum in industry. It was introduced to our mainstream business culture in the 1980s when Bill Smith an engineer for Motorola first introduced the concept.

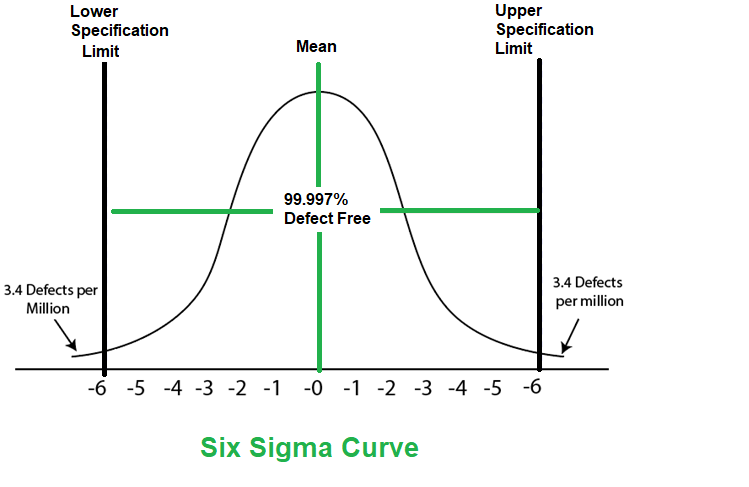

Six Sigma is a statistical approach which aims at achieving breakthrough improvement by reducing variation and defects.

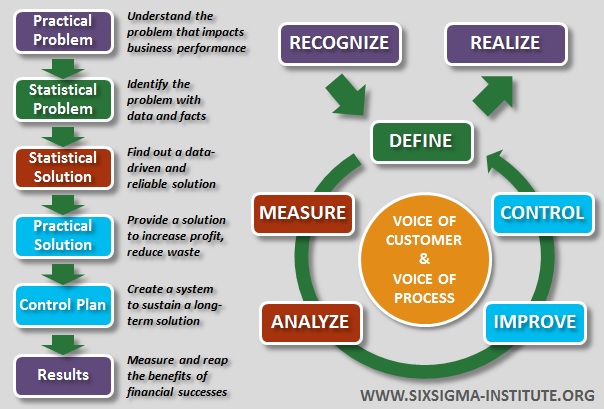

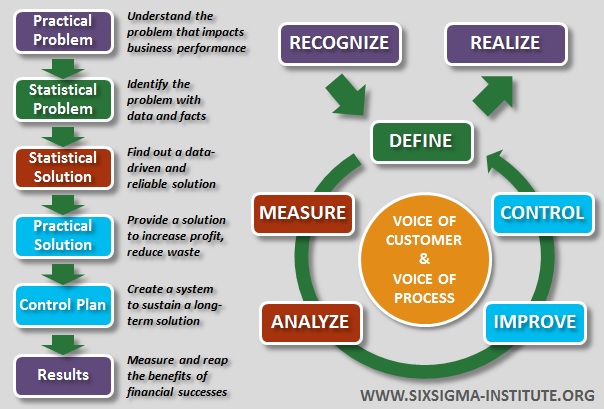

Six sigma definition. Carlson School of Management University of Minnesota USA bStrategic Improvement Systems LLC Excelsior MN USA cLally School of Management and Technology Rensselaer Polytechnic Institute USA Available online 22 June 2007. However academics have conducted little research on this emerging phenomenon. One of the most common six sigma framework is the DMAIC approach.

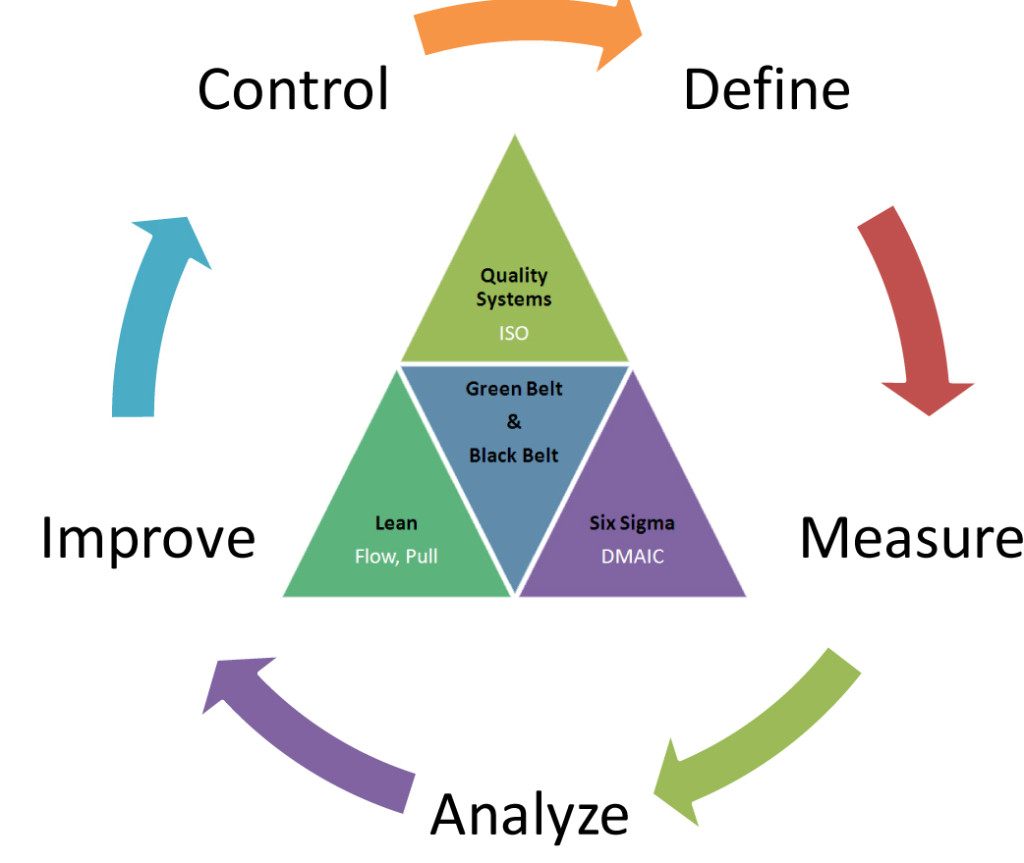

Lean six-sigma is well defined as a process improvement methodology that is mainly used to remove waste inefficiency eliminate hindrances and provide better customer requirements. Development of the Six Sigma system is. Definition and underlying theory Roger G.

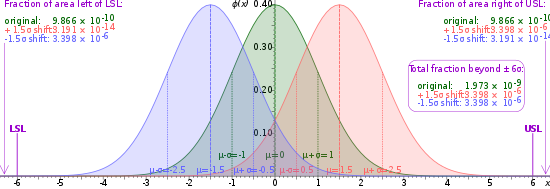

Six Sigma Certifications ASQ certification is a formal recognition that an individual has demonstrated a proficiency within and comprehension of a specific body of knowledge. Six Sigma is considered more important over other quality improvement techniques as -. Therefore the greater the number of ss smaller the variation the tighter the distribution around the average it will produce approximately 34 Defects Per Million Opportunities.

Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. Six Sigma A process quality measure indicating that there are 6 standard deviations between the process average and EACH lower upper specification limit. It combines lean manufacturing lean enterprise and Six Sigma to eliminate the eight kinds of waste muda.

Six Sigma Definition Six Sigma is a method of comparing organisation process performance with critical customer needs ensuring that business outputs its products and services are consistently designed to exact customer requirements. Improving cycle time while reducing errors to sigma levels below 34 defects in 1 million occurrences. Developed in 1986 by Motorola engineer Bill Smith Sigma Six is a data-driven quality control method designed to reduce defects and improve business processes hence achieving greater efficiency.

In other words it is a methodology to achieve 34 defects per million opportunities. Understanding Six Sigma first requires providing a conceptual definition and identifying an underlying theory. It requires thorough understanding of product and process knowledge and is completely driven by customer expectations.

Defects Over-Production Waiting Non-Utilized Talent Transportation Inventory. Six Sigma is a set of quality management techniques and tools developed in the 1980s and adopted by American corporations including General Electric. Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation.

Six Sigma is a framework that was designed to eliminate waste and improve the customer experience. Sigma Six Concept empathizes in two aspects. The technique aims to produce products that are virtually defect-free Antony and Banuelas 2002.

Today according to many business development experts Six Sigma is the most popular quality improvement methodology in history. Six Sigma - Definition its Origin Six Sigma is a data-based methodology to improve performance by reducing variability. It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit.

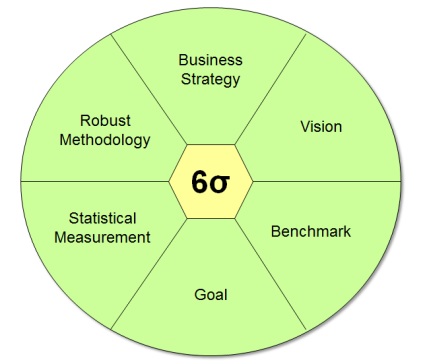

It combines tools and techniques methods and lean and six-sigma principles into a robust methodology to enhance organization performance. Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process -- from manufacturing to transactional and from product to service. Schroedera Kevin Lindermana1 Charles Liedtkeb2 Adrian S.

Chooc3 a Curtis L.

What Is Six Sigma And Why Is It Important Workzone

What Is Six Sigma And Why Is It Important Workzone

Statistical Six Sigma Definition

Statistical Six Sigma Definition

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Back To Basics Six Sigma 2018 01 01 Quality Magazine

Back To Basics Six Sigma 2018 01 01 Quality Magazine

Benefits Of Six Sigma For You And Your Organization

Benefits Of Six Sigma For You And Your Organization

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma Lean Manufacturing And Six Sigma Definitions

Six Sigma In Software Engineering Geeksforgeeks

Six Sigma In Software Engineering Geeksforgeeks

What Is Six Sigma Pyzdek Institute

What Is Six Sigma Pyzdek Institute

Dmaic A Six Sigma Process Improvement Methodology

Dmaic A Six Sigma Process Improvement Methodology

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

What Is Six Sigma International Six Sigma Institute

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

What Is Lean Six Sigma What It Is Why It Matters How To Do It Right

/Lean_Six_Sigma_Structure_Pyramid-671e13ecc9e84e6e922d961234f57124.png)

No comments:

Post a Comment

Note: only a member of this blog may post a comment.