Read on to learn more about the important connection between Lean and Agile. Total Time worked Touch Time 4 wk Lead TimeElapsed Time 21 weeks Idea worked for 2 hrs.

Lean Agile And Scrum A Simple Guide 2020 Brainhub

Lean Agile And Scrum A Simple Guide 2020 Brainhub

Well first see how both of these methodologies came into existence.

Lean agile principles. Ad Powerful project management software for teams. Demand rate of requirement arrival Vs Capability development throughput 3. In the 1980s computer programmers used traditional development approaches like the Waterfall methodology to manage their software development projects.

Measure performance report effectively get insights. It is the economic concept that informs the practices and role of the SAFe. 10 chief underlying principles help in effective enterprise management.

Start a trial today. Strategy to reduce Lead Time 1. Although separate in their tactical application each works to facilitate a similar end.

Lean-Agile methodologies are rooted in the underlying principles of both Agile and Lean development approaches. Adapted from the Toyota Production System it is emerging with the support of a pro-lean subculture within the Agile community. Eliminating waste in the work flow 3.

It uses both Lean principles and Agile practices. The SAFe methodology is an agile framework for product development teams. Ajit Alwe Topics Covered 1.

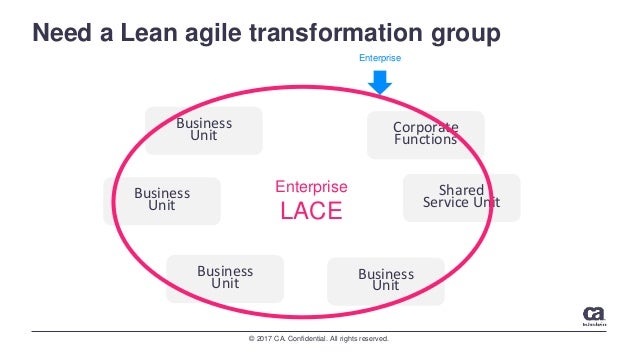

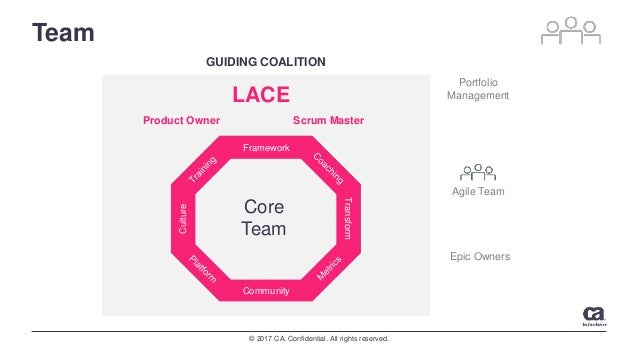

The lean transformation from agile to lean-agile at an enterprise level is achieved with the Scaled agile principles called lean agile principles. Produce sustainable results quickly. Agile and Lean methodologies in software development enable teams to deliver faster.

Built on three pillars Team Program and Portfolio it is designed to give flexibility to a team and help manage. Agile methodology combines values and principles that encourage better ways of developing softwarecentering on individuals and interactions capable technology customer collaboration and embracing change. Lean software development is a translation of lean manufacturing principles and practices to the software development domain.

Agile development is a process for rapid software delivery that is connected to many Lean principles. Lead Time and Process efficiency 2. Lean-Agile principles form an economic concept that informs the role and practices of the Scaled Agile Framework SAFe.

Ad Powerful project management software for teams. For project managers it helps to know the basic differences between the two approaches to understanding how one or the other best optimizes operational effectiveness in. Ad Agile estimation is hard to get right.

Lean Agile is a hybrid approach. Lean Agile is a set of principles and practices for working that aims to minimize waste whilst maximizing value. Lean offers a solid conceptual framework values and principles as well as good practices derived from experience that support agile.

Define lean agile principles. Not only was this process time consuming but it was also costly. Automated Deployment Pipeline Why Agile.

We augment your estimations with data and the best machine learning models. After all the Lean Agile differences start right here. A Lean Agile process has both elements of continuous delivery and continuous improvement.

Measure performance report effectively get insights. Start a trial today. The simple answer is this.

What are the Lean-Agile Principles. Lean and agile are two strategic approaches in the project management world domain.

.jpg)