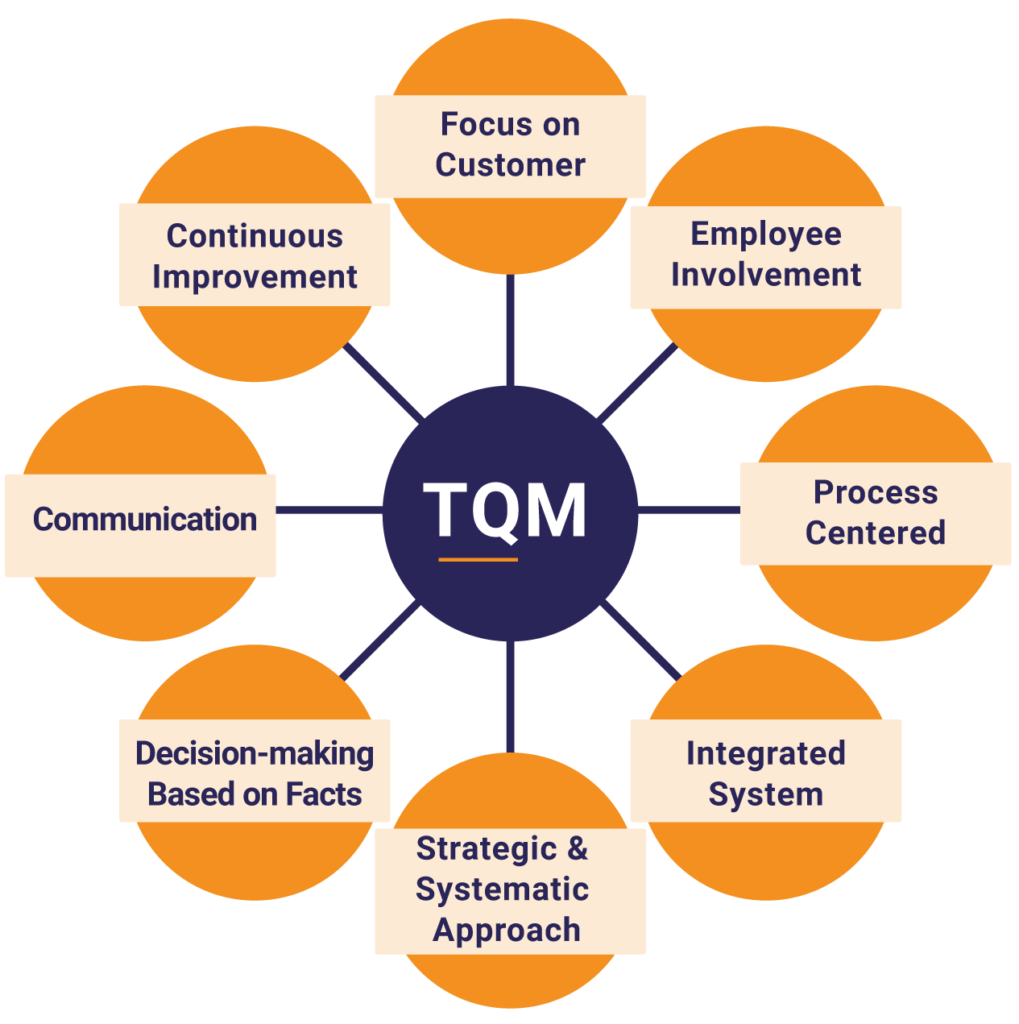

Pengertian Total Quality Management TQM Total Management System atau disingkat dengan TQM adalah suatu sistem manajemen kualitas yang berfokus pada Pelanggan Customer focused dengan melibatkan semua level karyawan dalam melakukan peningkatan atau perbaikan yang berkesinambungan secara terus-menerus. A core definition of total quality management TQM describes a management approach to long-term success through customer satisfaction.

Pengertian Karakteristik Metode Dan Manfaat Total Quality Manajemen Tqm Kajianpustaka Com

Pengertian Karakteristik Metode Dan Manfaat Total Quality Manajemen Tqm Kajianpustaka Com

Pada dasarnya Manajemen Kualitas Quality Management atau Manajemen Kualitas Terpadu Total Quality Management TQM didefinisikan sebagai suatu cara meningkatkan performancekinerja secara terus-menerus continuous performance improvement pada setiap level operasi atau proses dalam setiap era fungsional dari suatu organisasi dengan menggunakan semua sumber daya.

Total quality management tqm. Get Results from 6 Engines at Once. What is Total Quality Management. Process of TQM PDCA Modelhttpsyoutube4tn1-RmgfhsQuality CirclehttpsyoutubeI_C8h3M_FUEJoin telegram for all resources httpstmeskillics.

Lets take a look at these five core principles. Total Quality Management is an extensive and structured organization management approach that focuses on continuous quality improvement of products and services by using continuous feedback. Pengertian Total Quality Management TQM Total Management System atau disingkat dengan TQM adalah suatu sistem manajemen kualitas yang berfokus pada Pelanggan Customer focused dengan melibatkan semua level karyawan dalam melakukan peningkatan atau perbaikan yang berkesinambungan secara terus-menerus.

This can be achieved by integrating all quality-related functions and processes throughout the company. In a TQM effort all members of an organization participate in improving processes products services and the culture in which they work. Pengertian Total Quality Management TQM Total Quality Management TQM disebut juga dengan Manajemen Mutu Terpadu atau Manajemen Kualitas Terpadu merupakan pendekatan manajemen pada suatu organisasi berpusat pada kualitas berdasarkan partisipasi semua anggotanya dan bertujuan untuk kesuksesan jangka panjang melalui kepuasan pelanggan dan manfaat bagi semua anggota.

TQM atau Total Quality Management adalah sistem manajemen kualitas yang berfokus pada pelanggan dengan melibatkan semua level karyawan guna melakukan peningkatan atau perbaikan yang berkesinambungan. Get Results from 6 Engines at Once. According to international organization for standards defined tqm as TQM is a management.

Ad Search Software Contact Management. In a TQM effort all members of an organization participate in improving processes. Various Definitions Total quality management TQM has been defined as an integrated organizational effort designed to improve quality at every level.

Total Quality Management TQM also known as total productive maintenance describes a management approach to long-term success through customer satisfaction. Total Quality Management TQM is an approach that seeks to improve quality and performance which will meet or exceed customer expectations. Total quality management TQM consists of organization-wide efforts to install and make permanent climate where employees continuously improve their ability to provide on demand products and services that customers will find of particular value Total emphasizes that departments in addition to production for example sales and marketing.

Total Quality Management atau TQM menggunakan. Focus on the customer. The process to produce a perfect product by a series of measures require an organized effort by the entire company to prevent or eliminate errors at every stage in production is called total quality management.

Ad Search Software Contact Management. In other words the principles of total quality management center around the customer quality of work mutual respect and teamwork. Joseph Juran was one of the founders of total quality management just like William E.

Pengertian lainnya total quality management adalah strategi manajemen yang bertujuan menanamkan kesadaran kualitas pada semua proses dalam organisasi. Total quality management TQM is the continual process of detecting and reducing or eliminating errors in manufacturing streamlining supply chain. Total Quality Management atau TQM menggunakan.